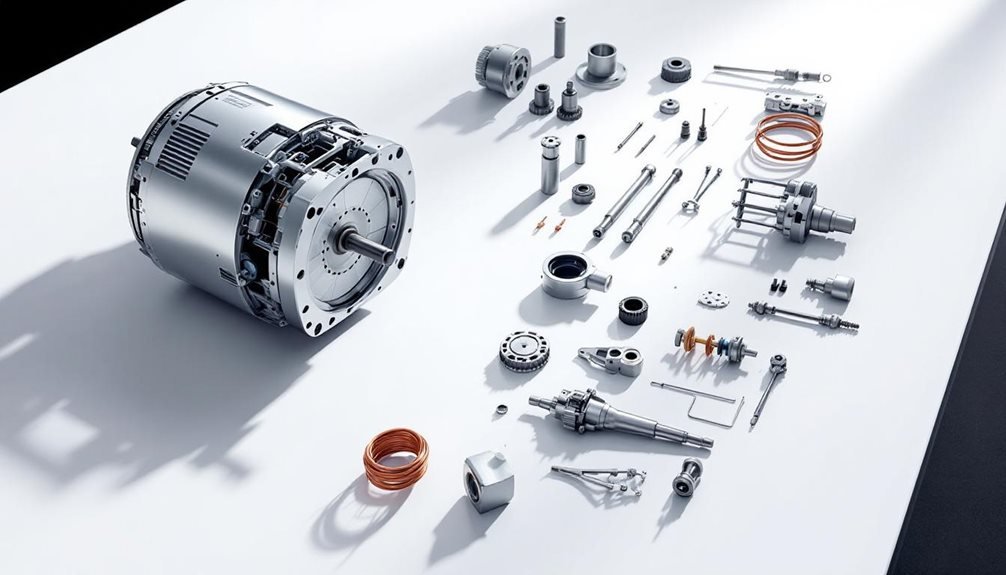

Tesla’s electric drivetrain operates with roughly 20 or fewer moving parts. That’s it. Compare this to traditional gas-powered cars that lumber around with over 1,000 moving components—pistons, valves, gears, clutches, and countless other bits waiting to break. Tesla’s setup includes one motor, about eight gear reduction components, plus axles and suspension elements. No fuel injectors, no complex transmissions, no mechanical headaches. This simplicity translates to minimal maintenance, fewer breakdowns, and service bills that won’t make you weep. The engineering elegance behind this efficient approach reveals fascinating implications for reliability and ownership costs.

How many moving parts does it take to drive a two-ton electric vehicle down the highway? For Tesla, the answer is surprisingly simple: 20 or fewer moving parts. That’s it. No joke. This minimalist design not only enhances reliability but also contributes to the efficiency that Tesla is known for. In addition to its mechanical advantages, the spacious interior and innovative features, such as the ample tesla trunk space dimensions, make these vehicles practical for everyday use. This combination of simplicity and functionality sets Tesla apart in the competitive electric vehicle market.

Compare that to traditional internal combustion engine vehicles, which pack over 1,000 moving parts under the hood alone. Add in transmission systems with their hundreds of gears, clutches, and linkages, and you’re looking at a mechanical nightmare waiting to happen. Tesla said “nope” to all that complexity.

The electric drivetrain is brutally efficient in its simplicity. One motor counts as one moving part. Throw in about eight gear reduction components, plus axles and suspension bits, and you’ve covered the essentials. Everything else? Gone. No pistons hammering away thousands of times per minute. No valves opening and closing like caffeinated hummingbirds. No fuel injectors squirting precisely timed bursts of gasoline.

This isn’t just about showing off engineering skill. Fewer parts mean fewer things can break. Basic math, really. When your drivetrain has 50 times fewer moving components than a traditional car, maintenance becomes almost boring. This simplified design also means increased reliability for Tesla owners who want dependable transportation. Moreover, fewer components not only streamline repairs but also enhance the overall longevity of the vehicle. For Tesla drivers, this translates into a less frequent need for part replacements, although it’s still essential to watch for common signs you need new tesla brakes. Regular inspections can help ensure that braking performance remains optimal, contributing to a safer driving experience.

Tesla service bills often range from zero to £400, while something like a Porsche Taycan can hit £1,500 or more for routine work.

The energy efficiency gains are real too. Single-speed gearing eliminates the energy losses that multi-speed transmissions create. Electric motors deliver torque directly, no intermediate mechanical gymnastics required.

Regenerative braking handles energy recovery through software, not additional hardware. EVs are showing 5 to 10 times better reliability than ICE systems overall.

Battery management systems replace fuel delivery mechanisms. Software controls replace mechanical linkages. Over-the-air updates fix problems that would traditionally require physical service visits.

It’s almost like Tesla designed these cars for people who have better things to do than visit service centers. Tesla’s simplified electrical architecture also enables versatile charging options, including the ability to charge from a portable generator during power outages or off-grid adventures.

The structural advantages add up quickly. Less friction, less vibration, longer intervals between maintenance. Modular battery systems keep things straightforward.

Even repairs become simpler when there aren’t a thousand tiny parts that could be causing problems.

Sometimes the most revolutionary approach is just removing everything unnecessary. Tesla figured that out.

Frequently Asked Questions

How Do Tesla’s Moving Parts Compare to Other Electric Vehicle Manufacturers?

Tesla keeps things stupidly simple compared to other EV makers. While Tesla’s drivetrain uses roughly 20 moving parts, competitors like Porsche’s Taycan apparently need more complexity. This simplicity not only enhances reliability but also contributes to lower manufacturing costs. Additionally, Tesla employs advanced tesla noise reduction techniques, making their vehicles quieter and more comfortable for drivers and passengers alike. This attention to detail sets Tesla apart in a competitive market where other manufacturers often prioritize complexity over user experience. This streamlined design contributes to fewer points of failure, making maintenance easier and often more cost-effective. However, potential buyers should weigh the pros and cons of Tesla ownership, as the lack of traditional features can be a drawback for some. Additionally, while the simplicity benefits performance and reliability, it may also limit customization options compared to competitors.

The proof? Taycan maintenance costs hit £400-£1,500, suggesting way more stuff that can break. Most EV manufacturers don’t publish exact moving parts counts, but Tesla’s minimalist approach clearly stands out. This focus on fewer moving parts contributes to lower maintenance costs over time, which is a significant advantage for many Tesla owners. Additionally, as the EV market evolves, consumers will want to consider elements like tesla wrap cost details 2025 when evaluating the long-term expenses associated with vehicle ownership. These factors highlight the growing importance of understanding both upfront costs and ongoing expenditures in the electric vehicle landscape.

Fewer parts, fewer headaches.

What Is the Average Lifespan of Tesla’s Moving Parts?

Tesla’s moving parts apparently last about 20 years, according to recent studies. But here’s the thing – nobody’s actually tracking individual part lifespans. This lack of tracking makes it difficult to verify general claims about longevity, including tesla battery life expectancy. Without specific data on each component, owners may not have a clear understanding of when to expect maintenance or replacements. As electric vehicles become more prevalent, establishing robust metrics for part longevity will be essential to enhance consumer confidence and ensure optimal performance.

The data just lumps everything together into broad vehicle longevity metrics.

Tesla’s ~20 moving parts face less wear than traditional engines, thanks to no pistons banging around or oil breaking down.

Still, those high-torque loads hit hard.

The real numbers? Total mystery.

How Much Does It Cost to Replace Tesla’s Most Expensive Moving Parts?

Tesla’s priciest moving part? The electric motor, naturally. Single motors run $3,000-$8,000+, but dual-motor AWD systems double that pain.

Gearbox replacements hit $1,500-$4,000 for complete assemblies. Differential work costs $2,000-$5,000, especially with those fancy planetary gears.

Even “simple” wheel bearings demand $200-$1,000 per side. Bottom line: Tesla’s fewer moving parts don’t mean cheaper repairs when things break.

Which Tesla Moving Parts Require the Most Frequent Maintenance or Replacement?

Tesla’s moving parts demand surprisingly regular attention despite the “low maintenance” hype. Cabin air filters top the list, needing replacement every 2-3 years depending on the model. Tires require rotation every 6,250 miles—more if you drive aggressively or hit potholes constantly.

Brake fluid gets swapped every four years. While brake calipers need annual cleaning in salty climates.

HEPA filters last three years if equipped.

How Has Tesla Reduced Moving Parts Compared to Their Earlier Models?

Tesla’s part reduction strategy is pretty aggressive. The Model 3 launched with roughly 10,000 parts compared to the Model S’s 30,000 parts from 2012. That’s massive simplification.

Single-body castings eliminated hundreds of components per vehicle, while the Model Y uses 30% fewer robots than Model 3 production. Tesla ditched traditional ICE complexity entirely – no engines, transmissions, or fluid systems. Software replaced mechanical functions.