While traditional automakers still rely on century-old assembly line methods, Tesla’s racing ahead with a radically different approach to building cars. The company’s new “Unboxed Process” works like building with Lego blocks, assembling vehicles in separate sections before putting them together at the end.

This revolutionary method promises to cut production costs by up to 50% and shrink factory space by 40%. Cars can be built 25% faster with 40% fewer workers needed. Tesla VP of Vehicle Engineering Lars Moravy calls the process “radical, crazy, and no one has pulled this off.” The approach is also known as Global Automotive Modular Evolution, or GAME.

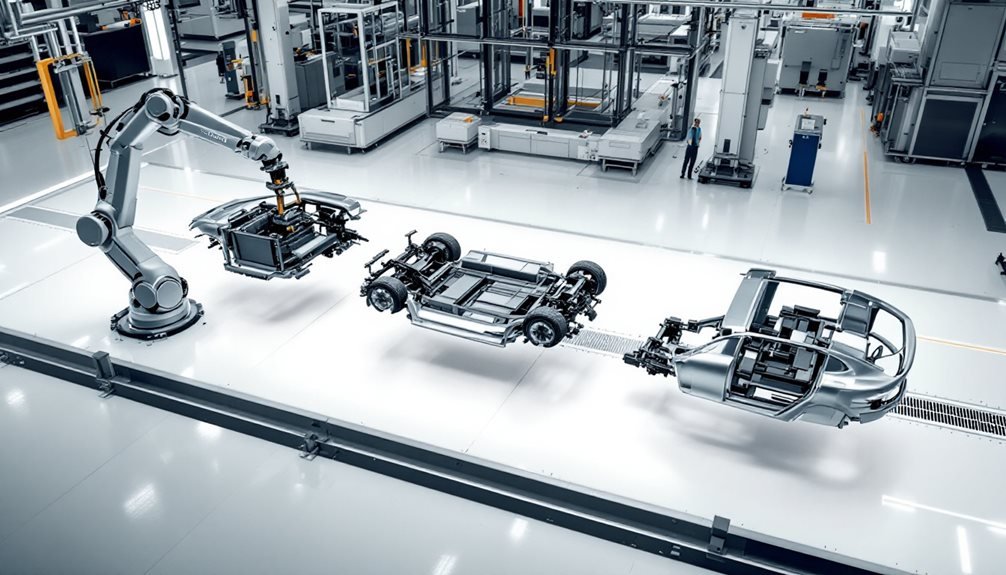

Instead of one long assembly line, Tesla builds different modules separately. Front sections, rear parts, batteries, and floor components come together only at final assembly. It’s a complete departure from how cars have been made for over a century.

Tesla’s modular assembly approach breaks from traditional automotive manufacturing by building vehicle sections separately before final integration.

Tesla paused Cybertruck and Model Y production at its Austin factory for a week starting June 30, 2025. The company executed at least three production shutdowns within 12 months for maintenance and improvements. Workers could use paid time off or join voluntary training sessions focused on improving work culture.

The timing matters because Tesla’s pushing to launch affordable electric vehicles. The company moved up production plans for new models, including a $25,000 Model 2. This vehicle represents Tesla’s goal to make electric cars accessible to more buyers. The strategy combines new and existing technology to speed up production without major investments in new manufacturing lines.

Meanwhile, competition’s heating up. Chinese rival BYD sold 3.02 million EVs and plug-in hybrids in 2024, beating Tesla’s total volume. Wuling’s MiniEV sold over 1.2 million units at under $5,000 in China. BYD’s setting up production in Mexico, potentially accessing U.S. markets while avoiding tariffs.

Tesla’s also shifting focus beyond cars. The company revealed Master Plan Part 4, emphasizing artificial intelligence and humanoid robots. Elon Musk predicts these Optimus robots might represent 80% of Tesla’s value. Production targets reach 5,000 units in 2025, scaling to potentially one million annually by 2030. Tesla’s Gigafactory in Texas is currently testing the Unboxed process with expansion plans to Mexico and Germany. Tesla reported a 13% year-over-year drop in first-quarter deliveries, with second-quarter numbers expected in July.